African Traditional Textile Patterns and their Origins

African textile pattern (Adinkra cloth symbol)

The African traditional textile patterns are a testament to the continent's rich cultural heritage and artistic diversity. These patterns, often characterized by vibrant colors and intricate designs, have been passed down through generations, each carrying its own unique story and significance.

Certainly! Here are some examples of traditional African textiles, along with their patterns, origins, and the Countries that continue to produce them today:

ADIRE CLOTH (Tie & Dye)

Adire, derived from the Yoruba term "adi" meaning "to tie" and "re" meaning "to dye," refers to an indigo reverse-dyed fabric originating from the "Egbaland" community in Abeokuta, Nigeria. This cloth, intricately tied and dyed, was initially crafted and worn by the people of Abeokuta. Historically, Abeokuta served as a prominent hub for cotton manufacturing during the nineteenth century.

Professional Artist, Nike Okundayo wearing a Traditional Tie & dye cloth. Photo source: Article from the Establishment -Sept 2019.

African heritage first model, Late Irene Mugambi in Nigerian Adire

Origin: Yoruba People, Nigeria

Pattern: Adire cloth is known for its indigo-dyed patterns, which are created using resist-dyeing techniques such as tie-dyeing, stitching, or stenciling. Common patterns include geometric shapes, botanical motifs, and abstract designs.

Origin of the Semiotics in Yoruba textile of Adire. Photo source: Semantic Scholar.

Adire patterns and dyeing techniques

Photo source: Pinterest

Production: The production of Adire involves several steps, regardless of the specific type:

Production of Adire Fabric

Preparation: The fabric, typically cotton, is prepared by washing and soaking to remove impurities and allow for better dye absorption.

Design Creation: Different techniques are used to create unique designs on the fabric. These include:

Tie-Dye (Adire Oniko): Fabric is tightly bound with strings or rubber bands to create patterns, then dipped into dye baths.

Stencil Printing (Adire Eleko): Stencils made from cassava paste are applied to the fabric, which acts as a resist against the dye.

Hand-Painted (Adire Alabere): Artists use brushes or sticks to apply dye directly onto the fabric, creating intricate designs.

Dyeing Process: The fabric is dyed using natural indigo dye or synthetic dyes, depending on the desired outcome.

Setting the Dye: After dyeing, the fabric is exposed to air and sunlight to set the colors and ensure they remain vibrant.

Finishing Touches: Any excess dye is washed out, and the fabric is dried and ironed to achieve a smooth finish.

Each type of Adire offers its own unique aesthetic and cultural significance, contributing to the rich tapestry of Nigerian textile artistry.

KENTE CLOTH

Kente cloth earned its name from "kenten," reflecting its basket-like weave. Each design carries a unique title and represents deep philosophical ideas expressed through vibrant colors and intricate patterns. Originating from the Akan people of Ghana in West Africa, Kente is meticulously handcrafted using strips of silk and cotton woven together.

African Kente Fabric

Origin: Ashanti Kingdom, Ghana

Pattern: Kente cloth is characterized by its vibrant colors and intricate geometric designs. Each design holds symbolic meaning, representing concepts such as unity, wisdom, and royalty.

Graphical representations of Selected Kente motifs. Photo credit: Research gate.

Kente Fabric with Adinkra symbols

Production: The production process of Kente fabric involves several key steps:

Weaving and patterning of the African Kente & Adinkra fabric

Yarn Preparation: High-quality silk and cotton yarns are carefully selected and dyed to achieve vibrant colors.

Warping and Sizing: The dyed yarns are warped onto a loom, ensuring proper tension and alignment. Sizing, a process involving starching the yarns, helps strengthen them and improves weaving efficiency.

Weaving: Highly skilled artisans weave the yarns on a traditional loom, meticulously following predetermined patterns. The intricate designs and vibrant colors are carefully crafted to produce the desired aesthetic.

Pattern Formation: Each strip of woven fabric, known as a "strip," is then sewn together to create larger panels. These panels can vary in size depending on the intended use of the Kente cloth.

Finishing Touches: After weaving, the fabric undergoes several finishing processes, including washing to remove sizing, and pressing to enhance the fabric's smoothness and luster.

Naming and Significance: Each Kente pattern holds symbolic meaning and is often named to reflect its cultural significance or the occasion for which it was created.

Overall, the production of Kente fabric requires a high level of skill, precision, and attention to detail, resulting in a textile revered for its beauty, cultural significance, and craftsmanship.

BOGOLANFINI (MUD CLOTH)

Bogolanfini, or Mud Cloth, originates from Mali, West Africa, crafted traditionally by Bamana artisans, predominantly women. The process involves weaving cotton strips, dyeing them with natural substances such as iron-rich mud, and drying them in the sun to create distinct patterns. These patterns often symbolize cultural aspects like mythology and social status. Bogolanfini has gained global recognition for its unique craftsmanship and cultural significance within Malian society.

African Mudcloth fabrics

Photo source: Pinterest

Origin: Bambara People, Mali

Pattern: Bogolanfini, or mud cloth, is characterized by its earthy colors and bold, abstract designs. The patterns are created using fermented mud, which is applied to the fabric in intricate motifs using hand-painted or block-printed techniques.

Mudcloth Camel Arrows fabric

Photo source: Spoonflower

Production: The production of mudcloth, also known as Bogolanfini, involves several key steps:

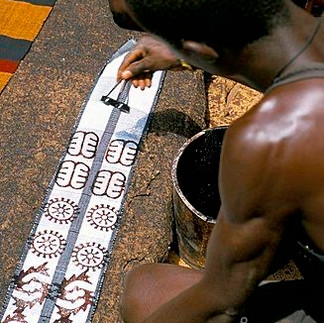

Mud cloth Patterning

Preparation of Cotton Fabric: High-quality cotton fabric is traditionally used as the base material for mudcloth. The fabric is washed and prepared to ensure it is clean and ready for dyeing.

Creation of Designs: Artisans use various techniques to create designs on the fabric. This can include hand-painting with natural dyes or applying resist materials such as mud, clay, or plant-based substances to create patterns.

Dyeing Process: The prepared fabric is dyed using natural dyes derived from sources such as plants, minerals, and mud. The application of these dyes results in the desired patterns and colors on the fabric.

Drying and Setting: After dyeing, the fabric is left to dry in the sun. This allows the colors to set and the patterns to become permanent.

Finishing Touches: Once dried, the mudcloth undergoes additional processes such as washing and sometimes bleaching to remove excess dye and enhance the appearance of the fabric.

Symbolism and Significance: Each mudcloth design often carries symbolic meaning, representing aspects of Malian culture, history, or spiritual beliefs. These designs may vary depending on the region and the artisan's creativity.

Overall, the production of mudcloth requires skilled craftsmanship and a deep understanding of traditional techniques. The resulting fabric is not only visually striking but also holds cultural significance within Malian society and beyond.

Malian textile artisan & some Mudclothes fabric

SHWESHWE FABRIC

Shweshwe fabric production has its roots in Lesotho, where it was introduced by European traders in the 19th century. Today, the fabric is primarily produced in South Africa, particularly in the Eastern Cape province. Shweshwe fabric remains popular among the Basotho and Xhosa people for traditional ceremonies and attire.

Shweshwe fabric

Origin: Basotho People, Lesotho

Pattern: Shweshwe fabric is characterized by its distinctive indigo color and intricate geometric patterns, including stripes, diamonds, and circles. Originally, the fabric was printed using copper rollers, but modern production methods may involve screen printing.

Pocket Mirrors covered in different South African Shweshwe Fabrics

Production: The production process of Shweshwe fabric involves several key steps:

Cotton Fabric Selection: High-quality cotton fabric is chosen as the base material for Shweshwe fabric. The fabric is typically tightly woven to provide durability and a smooth surface for printing.

Printing: Shweshwe fabric is traditionally printed using a process called discharge printing. This involves applying a bleaching agent to specific areas of the fabric to remove the dye and create patterns. The fabric is then washed to remove any excess bleach and dried before the next step.

Dyeing: After printing, the fabric undergoes a dyeing process to add color. Traditional Shweshwe fabric is known for its distinctive indigo blue color, although other colors may also be used. The fabric is dyed using natural indigo dye, which is derived from the leaves of the indigo plant.

Starching: Once dyed, the fabric is starched to give it stiffness and a characteristic crisp texture. This starching process also helps to set the dye and prevent it from bleeding.

Finishing: After starching, the fabric is washed to remove excess starch and dye. It is then dried and pressed to give it a smooth finish.

Final Inspection: The finished Shweshwe fabric is carefully inspected for quality and any imperfections are addressed before it is packaged and shipped for sale.

Overall, the production of Shweshwe fabric requires precision and expertise to achieve the distinctive patterns and colors that are characteristic of this traditional African textile.

Conclusively, these examples represent just a fraction of the diverse range of traditional African textiles still produced today. Each textile carries with it a rich history and cultural significance, reflecting the creativity, craftsmanship, and identity of the communities that continue to cherish and preserve these ancient traditions.

We hope you found the article informative and engaging. Your feedback in the comments is valuable to us as we strive to create content that resonates with our audience. Thank you for taking the time to read, we eagerly await your insight!

Comments